World

Accepted

Gear Technology

World Accepted Gear Technology

"REAL" 0 (Zero) Backlash

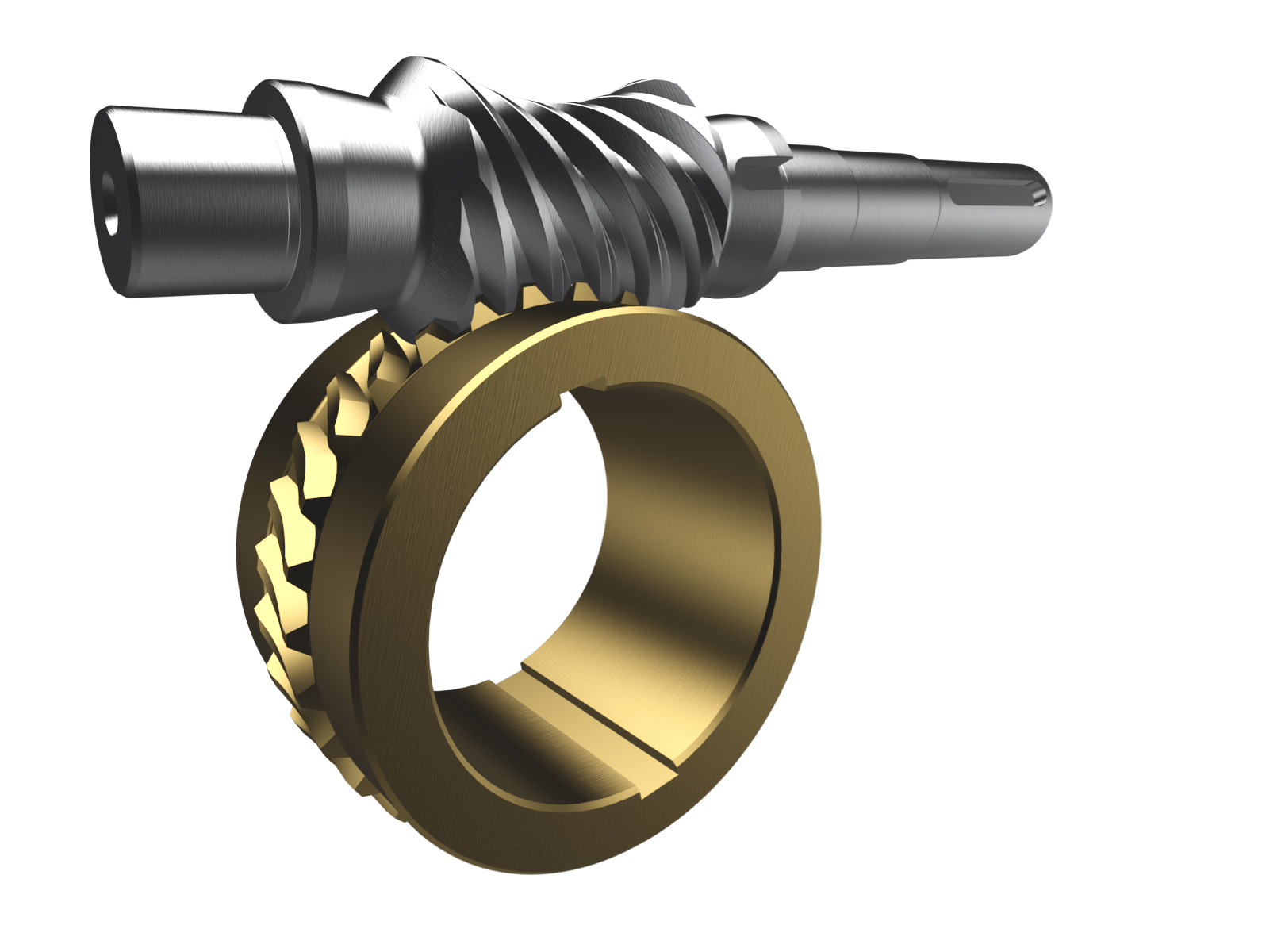

Globoidal gearsets have a completely unique way of operating when it comes to tooth profile. It is very difficult to tear the oil film due to the superficial contact between its teeth. Therefore, it is the only gear technology that provides TRUE ZERO BACKLASH in the world.

TurkRED™ offers a wide variety of precision driver solutions. We also offer special projects designing solutions for applications that require even higher precision.

The differences we have with the desire to constantly innovate and explore

Perfect Performance Under Varying Conditions

Long Life And Durability

High Protection Class

Some of the tests we provide are as following:» -30° + 60° operating condition test (72 hour cold start).

Temperature dependence backlash test:» 3 arcmin in every temparature value between -30° and +60°.» 72 hours salt test.» 72 hours 5% humidity test.

High Material Quality and Production Precision

TurkRED™ uses only the best quality material:Worm: AISI 4140 - DIN 1.7225 - 42CrMo4 - SCM440Wormgear: Aluminum Bronze (CuAl1Ni6Fe6) / Manganese Bronze (SAE 430B)Wormgear: Aluminum Bronze (CuAl1Ni6Fe6) / Manganese Bronze (SAE 430B)Output Shaft: AISI 4140 - DIN 1.7225 - 42CrMo4 - SCM440

New Generation, High Performance Gearboxes

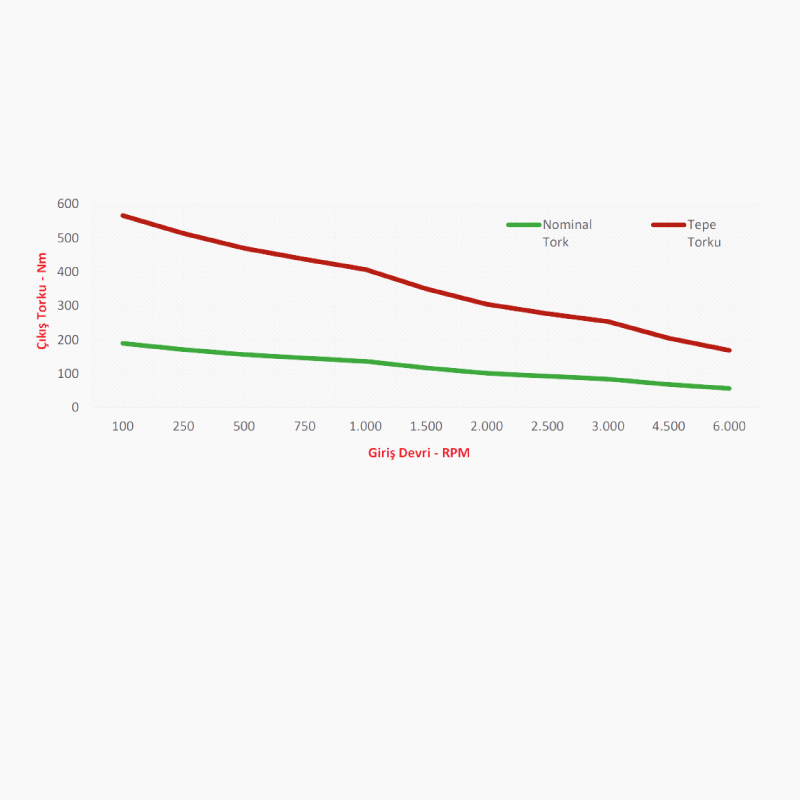

TurkRED™ gearsets deliver 300% more torque compared to the previous generation gearsets with its high performance, improved material quality used in production and high quality synthetic oil. You can access all our products’ torque levels here in our product configurator.

300% Peak Torque Capacity

300% Peak Torque Capacity

You will feel the difference with TurkRED

Methods and technologies that make TurkRED™ different and make it one step ahead of its competitors:

Globoidal Gearing Technology is the most advanced among the three of the most advanced gearing technologies known in the world, the two others being harmonic and cycloid. Unlike the other two, input and output shafts of a globoidal gearset stands at a perfect 90° angle. This makes Globoidal gearsets your only solution for high technology applications that require a 90° working angle.

The other two gearing technologies are often used particularly in robotic applications. Thanks to TurkRED™’s serial production capacity, we offer Globoidal Gearsets almost as closely cost-effective as its peers.

With years of experience in field, original designs, improved tooling technologies and original machines— Globoidal Wormgear Hobbing Machine, Wormgear Lapping Bench, Globoidal Wormgear Meshing Analysis and Backlash Measuring Machines, along with academic studies done by Ali Caner Ateş, a new method was developed that works with even higher performance than discussed in AGMA 96FTM12. Ali Caner Ateş named this design after his late father, Cevat Ateş. This method adopts full contact design discussed in AGMA 96FTM12 and takes it to a next and improved level. Such force of improvement in engineering (theoretical) as well as manufacturing (practical) is derived from our experience of 40 years in the field. All rights of this design are reserved by our company as know-how.

Our zero backlash reducers will save you the trouble of feedbacking processes with its high precision feature. With no position controlling required between the input and the output of the reducer, you won’t be needing any position feedback interface. This means that without spending time and effort on ensuring position precision, you will have an easy-top-apply, low maintenance and low cost gearset in your hands.

One of the best sources to get a better understanding of gearing technology is the article RP-1406 issued by NASA. With this publication, it is possible to get a better understanding of all known gear technologies in the world. Also, AGMA 96FTM12 standard mentions all known contact surfaces known for Globoidal Gears referring to many world-renowned scholars. Thanks to decades of experimentation, TurkRED™ has come up with new designs and manufacturing methods for helix angles, pressure angles, number of teeth in gear, tooth width, worm pitch and tooth radius, gear and worm root diameters, tooth width and backlash. All these parameters are used by our company to lay down standards for our manufacturing process with the aim of reaching absolute perfection.

Depending on the transmission rate, 3 to 11 teeth are in contact without separation during the working state. As a result, Globoidal Gears have an extremely high torque carrying capacity compared to other gear systems.By increasing the amount of teeth contact with gear worm, Globoidal technology radically raises Moment and shock resistance. In Run In & Run out states, no change can be observed that can discontinue contact. As a result, compared to other gears, Globoidal Gears carry much more weight. As far as the extent of current technical knowledge goes, there is no other gearing technology that can reach such high torque levels.

When we graph the data in the Transmission Ratio x Dimension x Torque trilogy, the results are truly incredible. We can easily see the power of Globoid technology and TurkRED.

H. Emine T.

I sincerely thank you for your friendly employees, the quality of your products, your solution-oriented approaches and fast deliveries. Working with you is a pleasure. Best regards to the TurkRED Team…

Candan K.

No matter how sensitive the driver we choose in all our automation projects, we realized the real difference when we switched to the zero-space TurkRED SensDrive product. It is a source of pride for such an important product to be of Turkish origin.

Kenan F. B.

When I want to describe the capability of our factory, I describe it before and after meeting TurkRED. TurkRED’s contributions to our company, which has truly undergone a revolutionary transformation, are enormous. Thank you.